Technical Description

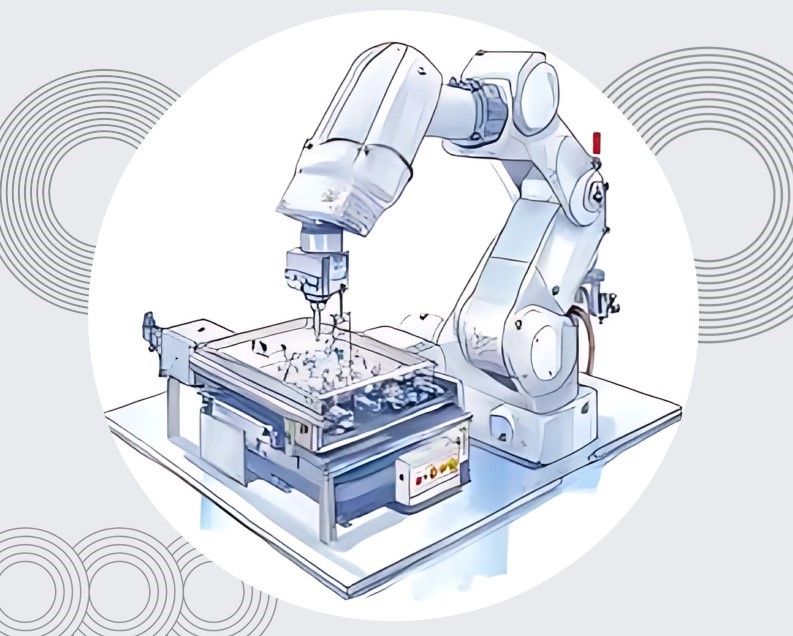

This invention introduces an auto-robotic vacuum-based screwing system designed for cluster assembly. It features real-time torque derection and automatic torque detection and automatic torque adjustment, ensuring precise screw insertion. improved accuracy, and enhanced productivity by reducing manual effort and errors.

Problems Addressed

- Inconsistent Assembly Quality

- Misaligned Components

- Low Screwing Precision

- Difficulty with Complex Tasks

- Limited Flexibility for Parts

- Manual Screw Handling

- Risk of Damaging Parts

- Slow Assembly Process

Tech Features

- Automatic Torque Adjustment

- Real Time Torque Detection

- Vacuum Screw Holding

- Predictive Maintenance System

- Error Detection Sensors

- Robotic Arm Integration

- Precision Screw Alignment

- Reduced Manual Effort

Target Audience

- Automotive Industry

- Electronic Industry

- Aerospace Sector

- Home Appliance Manufacturers

- Industrial Equipment Production

Tech ID: P18-1275 TRL 4 Patent Status: Granted Available For Exclusive and Non-exclusive License

×

P18-1275

DOWNLOAD

Send download link to email.